Do you know what plastic wood is? Three minutes to make you an entry-level WPC expert!

Do you know what plastic wood is? Three minutes to make you an entry-level WPC expert!Plastic wood composite materials, originated in North America, also known as: wood plastic, ecological wood, technology wood, recycled wood, its standard English name is: Wood Plastic Composites, so, also referred to as WPC.

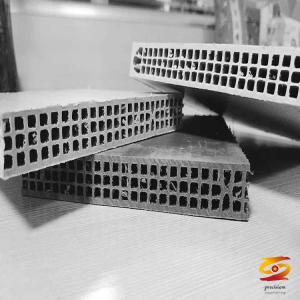

Plastic wood flooring

Plastic wood is mainly composed of wood fibers (biomass materials such as wood chips, bamboo chips, wheat straw, bran, peanut shells, cotton straws, etc.), and uses the characteristics of polymer interface chemistry and the characteristics of plastic filling and modification. The proportion of polyolefin plastic base material is a reversible recycling, basic material with various shapes and structures that is processed and shaped by a special process. It not only maintains the appearance and feel of solid wood flooring, but also has good moisture and water resistance, acid and alkali resistance, fungus suppression, antistatic, insect resistance and other properties, and wood-plastic products have high fire resistance, no pollution, no pollution, and can be recycled.

1. What is plastic wood? Where is WPC used? Plastic wood is a building material that is formed by extruding plastic and wood fibers at a certain ratio. Because it has both water resistance, corrosion resistance, mildew resistance and wood texture, it has become the first choice for outdoor building materials (floors, railings, stools, gazebos, flower stands, integrated houses, etc.).

2. What colors are available for plastic wood, do you need paint? Unlike wood, plastic wood does not require paint to have a variety of colors to choose from. And because of the special molding process of wood-plastic, it does not have the problem of discoloration.

3. Will plastic wood fade? Yes, wood plastic products exposed to sunlight and humidity will fade slightly after 10 ~ 12 weeks.

4. Is plastic wood more combustible than wood? The WPC profile is a Class C building material, and its combustion is similar to wood. After the combustion characteristics experiment, plastic wood is not easier to burn than wood. The burning temperature of wood-plastic needs to reach above 86 degrees.

5. Is quarantine required when exporting? Need fumigation? Do you need special supporting documents? No, unlike natural wood, due to the special process and formula of plastic wood, it is a fumigation-free product at the time of export and does not require any special certificate.

6. Is the plastic wood made of recycled materials? Yes. Plastic wood is processed using recycled polyolefin plastics and natural plant fibers such as waste wood chips or rice bran as raw materials.

Plastic wood flooring

7. What is the difference between plastic wood and plywood density board? Unlike plywood MDF (made of wood fiber and formaldehyde glue and pressed), WPC is made of plastic and wood fiber at a ratio of approximately 1: 2, completely free of formaldehyde glue. Because of the natural fiber, plastic wood has better UV resistance and lower thermal expansion and contraction performance, and is easy to process like wood.

8. What is the service life of WPC profiles? Under normal use conditions, the life of plastic wood products can reach more than 15 years. In public places with dense outdoor crowds, it is always tested by the flow of people and the environment. In such high-density occasions, the life of wood-plastic can reach 8 years. It can be up to 15 years.

9. Is plastic wood an environmentally friendly material? How to dispose of waste wood-plastic profiles? Will the waste wood and plastic cause pollution to the environment? The environmental significance of wood-plastic is multiple. On the one hand, it consumes waste plastics and wood powder that will pollute the environment. On the other hand, it can effectively replace the use of wood in the outdoors, thereby saving a lot of precious natural resources. Because it does not contain any toxic ingredients, it can be treated in the same way as other ordinary construction wastes without causing any pollution to the environment. Can be recycled 100%.

10. What is the weight of plastic wood compared to ordinary wood? Compared with the general wood, the ratio of plastic wood is much larger, usually above 1.1, and the general wood has a specific gravity of 0.4 ~ 0.7. Even the hardwood with a larger specific gravity has a specific gravity of only about 1.0. Therefore, the plastic wood is much heavier under the same volume and is therefore more durable.

11. How to process plastic wood, do you need special tools? Plastic wood is as easy to process as wood, and in some ways even easier. Only ordinary wood processing tools can be used to cut, drill and splice wood plastic.

12. What types of screws are suitable for wood-plastic profiles? It is recommended to use high-quality screws such as stainless steel and hot-dip galvanizing, especially threaded screws, and use electric drill guide holes before tightening the screws, which helps to increase the screw's grip.

13. Can WPC profiles be used for structural parts? No. Although ordinary plastic-wood profiles have high strength and toughness, they do not yet have the same rigidity as wood, so they cannot be used as structural parts. However, the modified fiber-reinforced plastic wood has high rigidity and can be used for structural parts.

14. Is the water absorption of plastic wood high? Since a plastic layer is wrapped around natural fibers such as wood fiber, the water absorption of wood plastic is very low. Very suitable for waterfront landscape.

15. Will low temperature / high temperature weather affect WPC? WPC products still perform well even in low-temperature weather, however, because plastic makes up more than 50% of the composition of WPC, it will be harder to punch holes in extremely low-temperature weather, in this case We recommend pre-drilling. When the temperature increases, the toughness of WPC will increase and there will be slight expansion. Therefore, maintaining proper span and spacing during installation is to counteract the impact of high temperature on the plastic wood.

16. How to maintain and maintain WPC? Even if it is exposed to the wind and sun in the outdoor, the wood-plastic material products will not rot, crack or crack, in addition to having the ability to resist ultraviolet rays, no maintenance is required.

If you want to know more about it please do not hesitate to

contact me. WhatsApp:+86-15966835076.