Introduction of bimetallic screw production process

Introduction of bimetallic screw production processThe bimetallic screw and barrel bimetallic process is a more commonly used process combination product with excellent corrosion resistance and wear resistance in recent years. The HVOF high-speed spraying equipment is used to melt spray spray the surface of the screw to obtain a densely structured bimetallic Screw; the bimetallic barrel adopts the method of melting casting, casting the alloy with high tungsten carbide composition into the barrel body, using special engineering technology, precision molding.

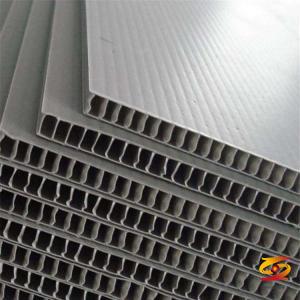

The bimetallic screw is a layer of 1-2mm wear-resistant, corrosion-resistant, high-temperature resistant alloy spray-welded on the inner wall of the barrel. Its effective service life is greatly improved compared with ordinary nitride barrels. For the formulation of high PVC calcium powder, increase The superiority of bimetal is especially obvious in the wear life.

Advantages of bimetallic screw:

Bimetallic screw is more wear-resistant, with good mixing effect and good dispersion.

If you want to know more about it please do not hesitate to

contact me. WhatsApp:+86-15966835076.