MPP cable protection tube construction process

1. Technical preparation before constructionA. Be familiar with and master the construction drawings before construction.

B. Prepare the corresponding construction equipment. Changchun is familiar with the construction of mpp pipe jacking

C. Conduct on-the-job training for the operating workers. Only after passing the training can the mpp jacking construction be carried out.

D. Check and accept the pipes and fittings according to the standard. Changchun is familiar with the construction of mpp pipe jacking

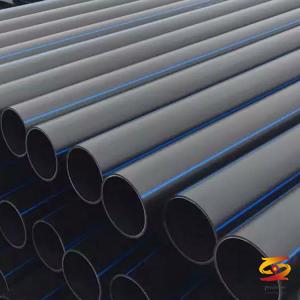

4. The mechanical strength of the mpp jack pipe is large: the pipe has good pressure resistance, impact resistance and tensile strength properties.

5. Simple construction: the pipeline connection construction is quick and easy, and the construction cost is low. Changchun is familiar with the construction of mpp pipe jacking

6. Low cost: low price, convenient transportation and construction, and long service life, so the overall cost is low.

7. The mpp jacking pipe will not affect the water quality: it has been confirmed by the dissolution test that it does not affect the water quality and is suitable for large-scale popularization and application.

In general, the mpp jacking tube has so many advantages, and it is because of these characteristics that the product has a wide range of applications. Of course, if the product plays a corresponding role, we need to purchase Good quality and low price products and follow the correct operation steps during the operation. Regular inspection and cleaning of the products in daily use to ensure that the products can play the corresponding role and extend the service life.

Due to the material properties of PE pipes, it is easy to absorb the heat in the air, so that the temperature of the water in the pipes rises, and the high temperature can reach about 50 ° C. Therefore, when the temperature is higher, the test pressure should be selected according to the actual water temperature to calculate the test pressure of the pipe.

5. Flat flaring should not be used

Cause: The taper of the flat flaring of the mpp top pipe water supply pipe is large, and it is difficult for the pipe and the flat end to be completely inserted into the bottom of the flat flaring, resulting in leakage of the pipe joint.

Solution: The water supply pipe is generally connected with a looper or directly bonded with a beam joint. Knowledge of the properties of Baoshan mpp pipe jacking

6. The expansion joint of the pipe hoop should not be used in the horizontal pipe

Reason: The sealing performance of the pipe expansion joint is poor, and it is easy to cause water leakage accidents when used in the horizontal pipe. Knowledge of the properties of Baoshan mpp pipe jacking

Solution: The expansion joint is generally used in the horizontal pipe to ensure that the pipe will not leak.

7. The temperature of the welded PE pipe should not be too high

Reason: Due to the characteristics of various materials, the material degrades at high temperatures, causing it to carbonize.

In summary, the matters needing attention in the construction of the mpp pipe jacking, in fact, the above matters are also the common mistakes and frequent mistakes in the pipeline construction, but it is often committed during the construction process.

Therefore, the construction quality will never reach the standard, resulting in problems in the future use process, which will affect the normal use, so pay more attention to the above items during the construction, so as to reduce the occurrence of problems, make the construction quality meet the standards and reduce the pipeline Of course, in the course of use, it is necessary to do corresponding inspection and maintenance work, so as to make the service life of the pipeline longer.

If you want to know more about it please do not hesitate to

contact me. WhatsApp:+86-15966835076.