Description

product description

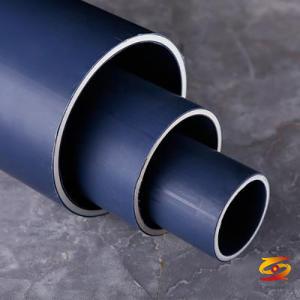

PPR pipe production line equipment is a new type of high-speed energy-saving production line developed based on the introduction of foreign technology by Qingdao Precision Machinery Co., Ltd. based on the actual domestic situation and the experience accumulated by our company for more than ten years. The operation is convenient and practical. This production line has the characteristics of beautiful appearance, high degree of automation and stable and reliable production.

1. The extruder is specially designed for PPR. It is equipped with a high-speed hardened gear reducer, a low-noise energy-saving fan cooling system, an automatic temperature control system and an automatic feeding and quantitative feeding system. Performance, increased filling, low temperature and high plasticization characteristics increase production.

2. The extrusion die is a high-pressure die unique to our company, which is forged and tempered by die steel and then plated. The special design of the mold core ensures the low-temperature plasticizing effect of the raw materials, and the special temperature control system of the core ensures the appearance and quality performance of the PPR pipe. The multi-layer co-extrusion die developed by our company has been trusted by many customers for its uniformity of melt pressure and flow rate and convenient adjustment performance.

3. The vacuum cooling water tank uses a two-stage vacuum system (only suitable for large-diameter pipes) and high-pressure water circulation. With advanced water level automatic water supply and drainage control and circulating water temperature control, it can easily realize the three-dimensional adjustment of up, down, left and right, and is equipped with two water channel control sizing devices. The unique pipe design effectively shortens the cooling length, which can definitely meet high-speed and stable Production requirements.

4. The traction machine adopts a special overall transmission design, which avoids the asynchrony and tremor of the independent transmission, and ensures flexible positioning orientation. The clamping adopts the mutual mode of electrical action, which is convenient for operation and the clamping pressure is well adjusted. .

PPR pipe production line equipment is a new type of high-speed energy-saving production line developed based on the introduction of foreign technology by Qingdao Precision Machinery Co., Ltd. based on the actual domestic situation and the experience accumulated by our company for more than ten years. The operation is convenient and practical. This production line has the characteristics of beautiful appearance, high degree of automation and stable and reliable production.

1. The extruder is specially designed for PPR. It is equipped with a high-speed hardened gear reducer, a low-noise energy-saving fan cooling system, an automatic temperature control system and an automatic feeding and quantitative feeding system. Performance, increased filling, low temperature and high plasticization characteristics increase production.

2. The extrusion die is a high-pressure die unique to our company, which is forged and tempered by die steel and then plated. The special design of the mold core ensures the low-temperature plasticizing effect of the raw materials, and the special temperature control system of the core ensures the appearance and quality performance of the PPR pipe. The multi-layer co-extrusion die developed by our company has been trusted by many customers for its uniformity of melt pressure and flow rate and convenient adjustment performance.

3. The vacuum cooling water tank uses a two-stage vacuum system (only suitable for large-diameter pipes) and high-pressure water circulation. With advanced water level automatic water supply and drainage control and circulating water temperature control, it can easily realize the three-dimensional adjustment of up, down, left and right, and is equipped with two water channel control sizing devices. The unique pipe design effectively shortens the cooling length, which can definitely meet high-speed and stable Production requirements.

4. The traction machine adopts a special overall transmission design, which avoids the asynchrony and tremor of the independent transmission, and ensures flexible positioning orientation. The clamping adopts the mutual mode of electrical action, which is convenient for operation and the clamping pressure is well adjusted. .