Description

The KTE/SE series two-stage extruder is

designed for use in heat-sensitive, shear-sensitive and high-filling areas.

Twin-screw extruders provide mixing and dispersing without excessive shearing,

and low-speed single-screw extruders provide sufficient cooling and pressure.

The SE series two-stage single screw is

suitable for recycling and granulating waste plastics with high moisture

content (about 10% moisture), dirty and light, with stable and uniform

discharge and high output. The equipment can be arranged in a straight or

L-shaped manner, with a compact layout, saving space and easy operation. Both

the upper and lower stage hosts are equipped with enlarged hydraulic screen

changers, which can effectively filter impurities, change screens without

interruption, greatly increase production, and the finished particles are firm,

full and glossy.

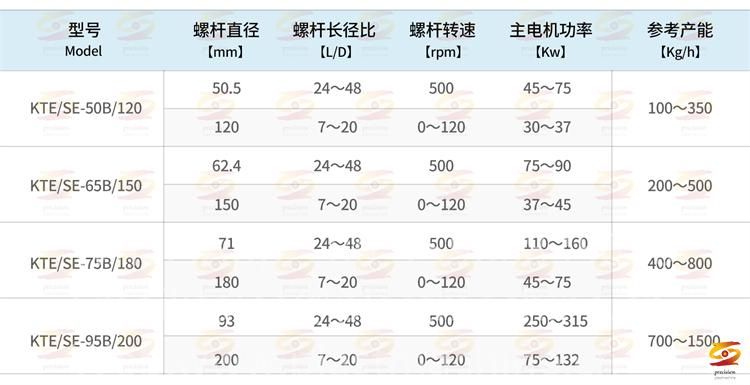

Specifications

Parameter table of two-stage mixing and

granulating unit

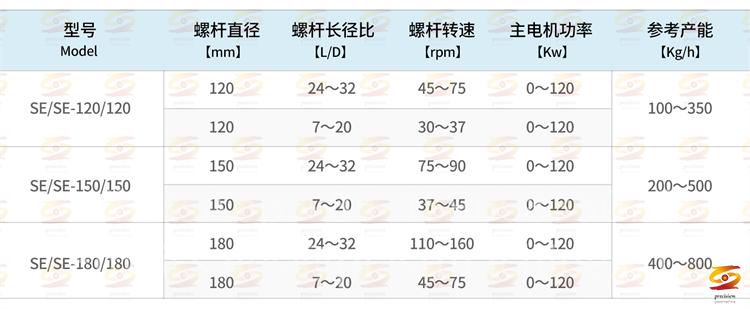

Two-stage single screw granulation extruder

parameters

Typical applications

KTE/SE series:

1) Cable materials

2) Wood and plastic blending granulation

3) EVA and foaming agent or cross-linking

additive granulation

4) XLPE granulation for cables or PEX pipes

5) High-concentration carbon black

masterbatch

SE/SE series:

1) Film recycling

2) Waste cloth/silk recycling

3) Soft and hard polyvinyl chloride

recycling

4) PP/PE and other crushed materials

recycling

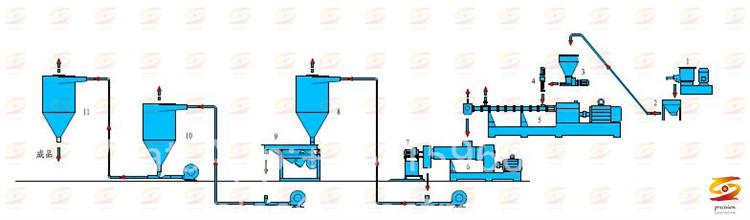

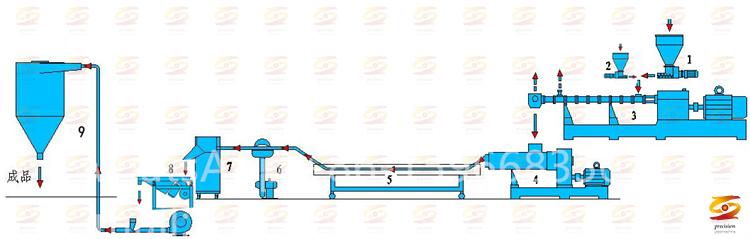

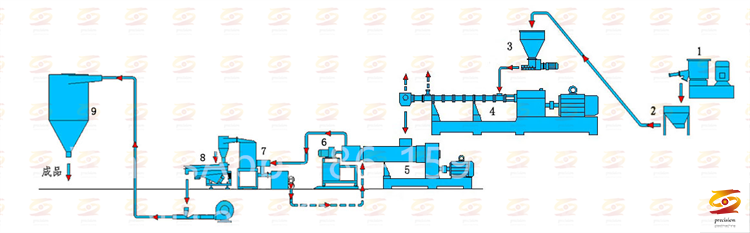

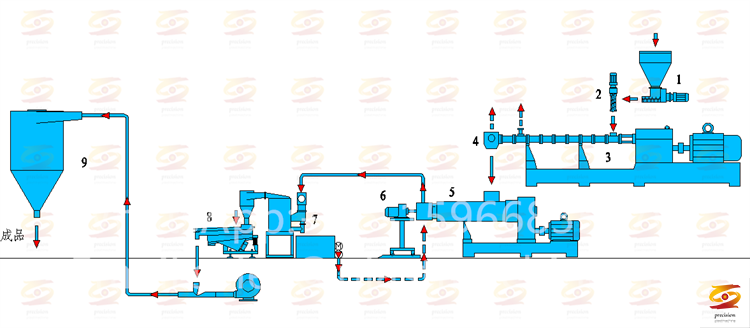

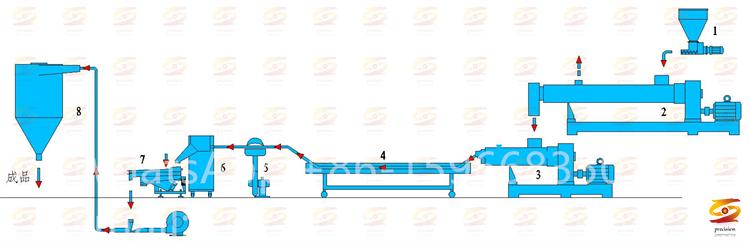

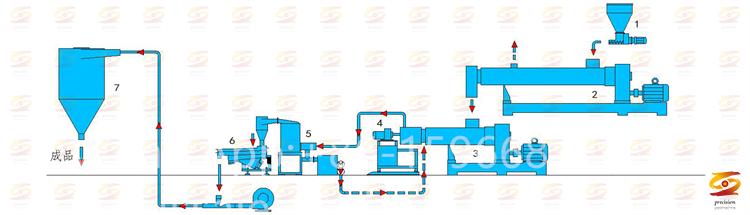

Equipment flow chart