Talk about some unknown advantages of XPS extruded board

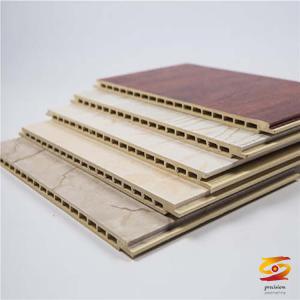

Talk about some unknown advantages of XPS extruded boardThe full name of extruded board is called extruded polystyrene foam board, also known as XPS board. Polystyrene foam is divided into two types: intumescent EPS and continuous extrusion XPS. Compared with EPS sheet, XPS sheet is the third generation of rigid foam insulation material. It overcomes the complicated production process of EPS sheet from the process , With superior performance that EPS board can not replace. It is a sheet made of polystyrene resin and other additives that has a continuous and uniform surface layer and a closed-cell honeycomb structure. It has no voids at all.

The extruded board is a polystyrene resin supplemented with a polymer, which is heated and mixed, and injected with a catalyst, and then extruded and extruded a continuous closed-cell foamed rigid foam plastic board. An environmentally friendly thermal insulation material with excellent properties such as high pressure resistance, low water absorption, moisture resistance, air permeability, light weight, corrosion resistance, ultra-aging resistance (almost no aging for long-term use), and low thermal conductivity.

XPS extruded plastic board is a new type of thermal insulation building material. It is well known and well known that XPS extruded plastic board has the characteristics of good thermal insulation and heat insulation, and can play a good role in thermal insulation. However, XPS extruded board not only has these advantages, but also has some features of location recognition. Here, one by one, Shanghai extruded board manufacturers introduce to you.

If you want to know more about it please do not hesitate to

contact me. WhatsApp:+86-15966835076.

Talk about some unknown advantages of XPS extruded board

1. Compression and impact resistance, excellent strength

The closed-cell structure of the extruded board is closely connected and there is no gap between the walls, so its compressive strength is extremely high, the extruded board has a great bearing capacity and good impact resistance, and can adapt to long-term load requirements.

2. Seepage and water resistance, stable performance

The extruded board has excellent anti-permeability, and it is a good water-resistant and moisture-proof material. Even after a long period of blistering, its physical properties can remain unchanged.

3. Easy construction and low cost

The honeycomb structure of the extruded board makes it have excellent strength, but it is not as brittle as polyurethane foam and phenolic foam: therefore it is not easy to break, and it is easy to handle, not damaged, and easy to cut, so it is easy to transport and install. The extruded plastic board has large strength and small bulk density, and it will not affect the bearing capacity of the structure too much when used as a wall insulation, so it will not increase the engineering cost due to it.

4. Not easy to degrade, environmentally friendly products

The extruded board is chemically stable, not easily degraded, will not decompose and mildew, and does not evaporate harmful substances; at the same time, it will not produce harmful gases and waste water during the production process, and the solid scraps formed can also be recycled for reuse Plastic board is a high-quality environmentally friendly product.