The application and economic value of the products of the PE water supply pipe production line

The application and economic value of the products of the PE water supply pipe production linepe (polyethylene) material is widely used in the field of water supply pipe manufacturing because of its high degree, corrosion resistance and non-existence. Because it will not rust, it is an ideal pipe to replace ordinary iron water supply pipes. The standard for PE water supply pipes is GB/T 13663-2000, "my country’s plastic pipes have developed rapidly and their quality has continued to improve. Polyethylene polyethylene pipes are widely used in building water supply, building drainage, buried drainage pipes, building heating gas pipes, and electrical Protection sleeves, industrial pipelines, agricultural pipelines, etc. Because of its unique advantages, it is mainly used in the fields of urban water supply, urban gas supply and farmland irrigation.

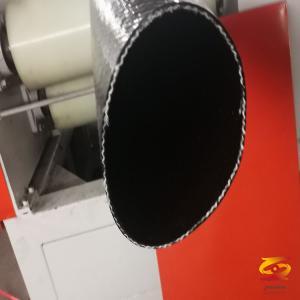

PE water supply pipe production line

The economic value of the performance advantages of PE water supply pipe production line

1. The flexibility of polyethylene piping system has economic value. The flexibility of polyethylene is an important property, which greatly increases the value of pipeline engineering materials. Good flexibility allows polyethylene pipes to be coiled and supplied in longer lengths, avoiding a large number of joints and pipe fittings. At the same time, flexibility, light weight and excellent scratch resistance make it possible to adopt various installation methods, which can reduce the impact on the environment and social life, and are cost-effective, such as excavation-free construction. Excavation-free construction refers to the construction of laying, replacing or repairing various underground pipelines without trenching (grooving) on the surface through various rock and soil drilling methods. Various excavation-free constructions are very suitable for polyethylene pipes, such as horizontal directional drilling and directional drilling to lay new pipes, in-situ expansion and replacement of old pipes, insertion and renewal of lining to repair old pipes, and various improved lining methods (Folding deformation method, hot stretching method and cold rolling method).

PE water supply pipe production line

2. PE's unique flexibility also enables it to effectively resist underground movement and terminal loads. On the surface, the strength and rigidity of plastic buried pipes are not as good as cement pipes and metal pipes, but from the point of view of practical applications, plastic buried pipes are "flexible pipes". Under the correct design and construction, the buried plastic pipe and the surrounding soil bear the load. Therefore, the plastic buried pipeline does not need to achieve the same strength and rigidity as the "rigid pipeline" to meet the mechanical performance requirements in buried use.

If you want to know more about it please do not hesitate to

contact me. WhatsApp:+86-15966835076.