The difference between two temperature control methods of extruder equipment

The difference between two temperature control methods of extruder equipmentThe temperature control system of the extruder and extrusion equipment is different according to the type of extruder. The two common temperature control methods are air cooling and water cooling.

The extruder is divided into several temperature zones according to different models, generally divided into the barrel temperature zone, the head temperature zone, and the barrel temperature zone is divided into several temperature zones according to different stages, most of them adopt automatic temperature control In the instrument, when the temperature is lower than the set value, the electric heating coil automatically turns off after reaching the set value. After the shear heat is overheated, it is cooled by air or water.

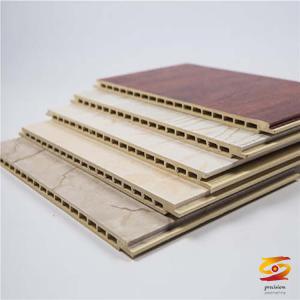

Extrusion equipment

Air cooling is to reduce the temperature of the problem of the screw area controlled by the fan. When the temperature drops to the required value, the air supply will be automatically stopped.

Similarly, the water cooling method usually uses a mold temperature machine to increase or decrease the temperature of each area of the screw. The water temperature control device is much more accurate than air cooling, so many extruders configured for the production of temperature sensitive materials use water cooling to control the temperature of the equipment.

If you want to know more about it please do not hesitate to

contact me. WhatsApp:+86-15966835076.