What are the advantages of carbon spiral tube equipment?

What are the advantages of carbon spiral tube equipment?Carbon spiral pipe equipment manufacturers explain the advantages of energy-saving and high-efficiency PE carbon spiral pipe equipment:

1. It is equipped with a special single-screw extruder for polyolefin, which has the advantages of high-speed extrusion and high-speed plasticization.

2. Dedicated separate mixing screw and spiral structure head, reasonable flow channel, smooth inner and outer walls of the pipe.

3. Specially designed sizing cooling method, the direct production range is 50-200mm, and the production speed is up to 3 meters/min.

4. Spiral distribution type fluid distribution, large flow space, to ensure that the melt has enough residence time.

5. Good design with low melting temperature, small internal stress of the pipe, smooth inner and outer surfaces.

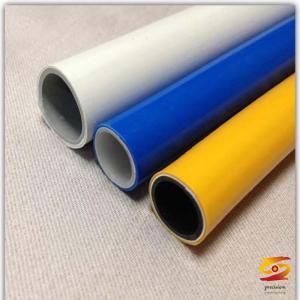

6. High flexibility, suitable for co-extrusion of all polyolefin materials, two-layer and three-layer spiral reinforced pipes with different specifications and uses can be extruded.

7. Optimized design of copper spiral sizing sleeve, with a pre-cooling device and a powerful suction vacuum device at the entrance, which is suitable for high-speed extrusion of the pipe.

8. Longitudinal movement motor adjustment, three-dimensional adjustment can be achieved up, down, left and right.

9. The box body is made of 3mm stainless steel.

10. High-efficiency water pump and special spray head bring efficient spray cooling.

Advantages and uses of pipe material: PE carbon spiral electric power communication buried bushing is made of high-grade HDPE as the main material, adding carbon fiber and PE modified color masterbatch to be extruded. It is an ideal buried underground for the construction of urban power communication lines. Pipe. Because of its smooth inner wall spiral structure, it effectively reduces the friction to the wire and optical cable compared with the flat-wall tube. The direct friction coefficient is reduced by 60% compared with the flat-wall tube. Because of its unique inner wall spiral, it provides wires and optical cables. It has a good ventilation and heat dissipation space, which effectively extends the service life of wires and optical cables, reduces maintenance costs, and is an ideal product for power communication departments to reduce operating costs. PE carbon spiral electric power communication buried casing has the advantages of high impact toughness, corrosion resistance, seismic performance, etc., and has a very strong ability to adapt to changes in ground settlement. The product has a single-wall inner and outer spiral structure, and uses a coil packaging process. Because a steel wire for pulling the wire is placed inside, it can provide convenient conditions for construction. The pipe is equipped with inspection wells according to the diameter requirements and is constructed without joints, which can ensure that the pipe does not leak, ensure the safety of the wire and optical cable, and reduce the construction cost. The PE carbon spiral electric power communication buried bushing solves the long-term problems that have plagued the power supply and communication departments such as the complexity, danger, theft, and high maintenance costs of urban overhead operations. PE carbon spiral electric power communication buried bushing is an ideal environmentally friendly and safe product.

If you want to know more about it please do not hesitate to

contact me. WhatsApp:+86-15966835076.