What are the performance advantages of using PMMA / PC materials in LED lampshades?

What are the performance advantages of using PMMA / PC materials in LED lampshades?LED tube shell, PMMA / PC material used in pc lampshade, chemical name Poly polymethyl methacrylate, polymerized by MMA monomer. Referred to as PMMA, commonly known as acrylic, acrylic.

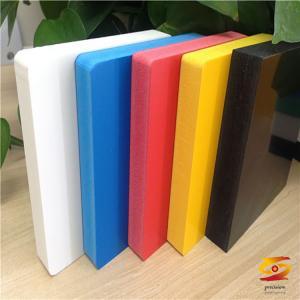

The LED lampshade is a thermoplastic with a density of 1.19-1.20, a very high transparency, a transmittance of up to 91% -93%, visible light 99%, ultraviolet light 72%, light weight, and anti-cracking performance of ordinary silica 12-18 times, mechanical strength and toughness are more than 10 times that of ordinary glass, the hardness is more than 2H before the end of the treatment, the surface hardness after surface strengthening can reach more than 5H, scratch resistance, with outstanding weather resistance and aging resistance, It has the same impact strength at low temperature (-50-60 ℃) and higher temperature (below 100 ℃), has good electrical insulation properties, can withstand arcs, has stable chemical properties, and can resist general chemical corrosion. The common thickness of PMMA material is 0.65 / 0.8 / 1.0 / 1.2 / 1.5 / 2.0 / 3.0MM, and the material color is available in other colors besides transparent. In addition, the surface of the plate can be coated. NI, CR, AL can be plated according to customer requirements Wait, the light transmittance is specified by the customer.

What are the performance advantages of using PMMA / PC materials in LED lampshades?

The LED lampshade is the abbreviation of polycarbonate, and the English of polycarbonate is Polycarbonate, abbreviated as PC engineering plastic. PC material is actually one of the so-called engineering plastics. As a widely used material worldwide, PC has its With its own characteristics, advantages and disadvantages, PC is an amorphous thermoplastic resin with excellent comprehensive properties. It has excellent electrical insulation, extensibility, dimensional stability and chemical resistance, high strength, heat resistance and cold resistance. Sex; also has the advantages of self-extinguishing, flame retardant, non-toxic, colorable, etc., you can see the shadow of PC plastic in every corner of your life, the characteristics of large-scale industrial production and easy processing also make its price extremely low. Its strength can meet various needs from mobile phones to bullet-proof glass. The disadvantage is that it has insufficient hardness compared to metal, which leads to its appearance being more easily scratched, but its strength and toughness are very good, whether it is heavy or ordinary As long as you are not trying to stone it, it will be long enough. The surface hardness of the PC material after surface treatment has been greatly improved, and the pencil hardness of the improved PC surface is generally around 2H.

Because the above two materials have good light transmittance, the surface is smooth and clean, there is no nozzle glue on the periphery after processing into the product, and there is no injection water mark on the surface. The PMMA sheet has a pencil hardness of 5H or more and is not easy to break. Acrylic lens development cycle is short, it can be as fast as two or three days from receiving the customer's image to sampling. There is no need to make molds, so it can be produced in small batches. The shape and size of the products can be changed flexibly. It can also process parts such as steps, assembly bayonet, earpiece holes, and beautiful lines. Due to the above advantages, it is now widely used in various high-end consumer digital products, such as mobile phone lenses, MP3 / MP4 lenses, digital camera camera lenses, signs, and other digital products. LCD \ TFT protective screens, automotive instruments can be Products such as video screens that need to be protected and decorated windows or panels. After the LED lampshade material is processed, the surface can be made into various patterns such as CD pattern, hairline pattern, etc. It is widely used in ultra-thin keys and other decorative surfaces of mobile phones.

If you want to know more about it please do not hesitate to

contact me. WhatsApp:+86-15966835076.