What is the principle and application of single screw extruder?

What is the principle and application of single screw extruder?The single-screw extruder is mainly used to extrude thermoplastics such as soft and hard polyvinyl chloride, polyethylene, etc. It can process a variety of plastic products, such as blown film, extruded tube, platen, pulling ribbon, etc., and can also be used for melt granulation. The plastic extruder has advanced design, high quality, good plasticization and low energy consumption. It adopts involute gear transmission and has the characteristics of low noise, smooth operation, large bearing capacity and long life.

The single-screw extruder is generally divided into three sections in terms of effective length. The effective length of the three sections is determined according to the screw diameter, pitch, and screw depth.

The high-efficiency single-screw extruder adopts a two-stage overall design, which strengthens the plasticizing function, ensuring high-speed and high-performance stable extrusion, and a special barrier comprehensive mixing design to ensure the mixing effect of the materials, high shear and low melting plasticizing temperature Ensure the high-performance low-temperature low-pressure metering extrusion of materials. Design concept and characteristics: high-speed, high-yield extrusion based on high straightness.

The principle of single screw extruder:

The last thread of the feed opening starts to be called the conveying section. The material here needs to be not plasticized, but it needs to be preheated and compressed by compression. In the past, the old extrusion theory believed that the material here was loose, and later it was proved that the material is actually solid. Plug, that is to say, the material is a solid like a plug after being squeezed, so as long as the conveying task is completed, it is its function.

The principle of the single screw extruder: when the second section is called the compression section, the volume of the screw groove is gradually reduced from large to large, and the temperature must reach the degree of plasticization of the material. The compression occurs here from the conveyor section three, where it is compressed to one. The compression ratio is 3:1, and some machines are also changed. The plasticized material enters the third stage.

The principle of single-screw extruder: The third section is the metering section where the material maintains the plasticizing temperature, but it delivers the melt material accurately and quantitatively as the metering pump to supply the machine head. At this time, the temperature cannot be lower than the plasticizing temperature, generally Slightly higher.

The single-screw extruder is mainly used for extruding thermoplastics such as soft and hard polyvinyl chloride, polyethylene and other plastics. It can be used with various auxiliary machines (including forming heads) to process a variety of plastic products, such as films, tubes, Plates, ribbons, etc. can also be used for granulation.

The plastic extruder has advanced design, high quality, good plasticization and low energy consumption. It adopts involute gear transmission and has the characteristics of low noise, smooth operation, large bearing capacity and long life.

Single screw extruder uses:

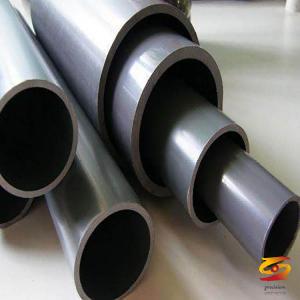

Pipe extrusion: suitable for PP-R pipes, PE gas pipes, PEX cross-linked pipes, aluminum-plastic composite pipes, ABS pipes, PVC pipes, HDPE silicon core pipes and various co-extruded composite pipes.

Sheet and sheet extrusion: suitable for the extrusion of PVC, PET, PS, PP, PC and other profiles and sheets. Extrusion of various other plastics such as silk, rods, etc.

Extrusion of profiles: adjusting the speed of the extruder and changing the structure of the extrusion screw can be applied to the production of various plastic profiles such as PVC and polyolefin. Modified granulation: suitable for blending, modifying and enhancing granulation of various plastics.

If you want to know more about it please do not hesitate to

contact me. WhatsApp:+86-15966835076.