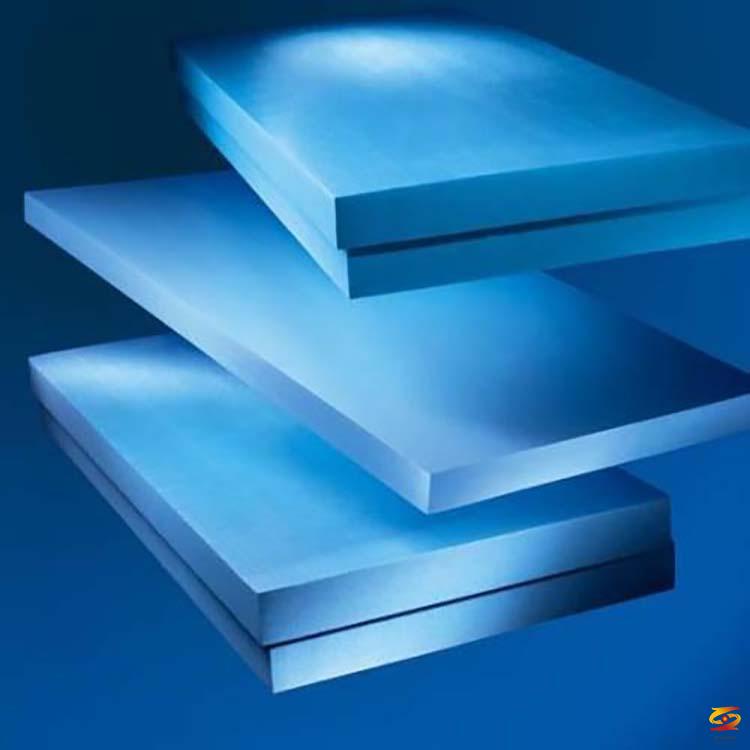

XPS foam insulation board performance and application analysis

XPS foam insulation board performance and application analysis3, the application scope of XPS in the construction field 1. Thermal insulation materials in composite walls: This kind of wall is like a sandwich biscuit, and XPS is the middle sandwich layer, its role is to prevent the wall It exchanges heat flow with the outside world, thereby playing the role of heat insulation; 2. The foundation of the underground wall of the building: in the cold area, frequent infiltration of frost often occurs, and the ground freezes and expands, and the base structure is damaged. Due to the low water absorption of XPS, it has good moisture and water resistance for underground buildings. XPS is placed under the base layer, which can minimize frost penetration and the formation of icing on the foundation susceptible to frost, and effectively control the ground frost heaving; 3. Roof insulation and external insulation: When XPS is used for internal insulation, usually Used in combination with other materials such as gypsum board, for external insulation, use special adhesives and fixing parts to cover XPS on the outer layer of the wall, and then external decoration; 4. Roof insulation: The more famous method is to invert the roof , That is, first complete the construction of the roof waterproof layer, and then do insulation on the waterproof layer; 5. Highways, airport runways, parking lots and other places that need to prevent pavement slushing and pressure resistance; 6. Cold storage equipment such as cold storage: XPS It can maintain important structural characteristics in the environment of freezing and thawing cycles, so it is suitable for use under freezing and thawing conditions.

4. Raw materials, technological process and equipment The main raw material of XPS is polystyrene resin, with an average molecular weight ranging from 170,000 to 500,000, Mw/Mn≥2.6, and auxiliary materials including additives, foaming agents, etc. Most of the blowing agents used by foreign companies do not contain halogenated carbon, but use hydrocarbon blowing agents with a faster replacement rate with air. In this way, the destruction of the ozone layer is avoided, and the replacement with air is mostly completed in the initial stage of the reaction, so that the thermal conductivity of the material changes little after construction. 1. XPS production process flow: raw material compounding → melt extrusion foaming agent (injection) → cooling → cutting → packaging → storage 2. main equipment and parameters: 1), mixing machine (500/1000) 2), Foaming agent injection pump station 3), tandem extruder (120-150) length-to-diameter ratio: 38:1 driving power: 110KW speed regulation mode: frequency conversion speed regulation 4), hydraulic quick screen changing device &5), positive pressure cooling Setting device (6), driving power of traction machine: 5.5KW Speed regulation mode: frequency conversion speed regulation 7), polystyrene bracket 8), cutting machine 9), automatic stacking platform 10), low temperature extrusion die product specifications: ( 600-900) X (25-60) MM 11), full-line control system 3. Production capacity: The annual production capacity of each production line is between 50,000 cubic meters and 100,000 cubic meters.

5. Application prospects of XPS For developed countries, the market for thermal insulation materials is huge. According to incomplete statistics, its per capita sales are 0.76 cubic meters in the United States, 0.70 cubic meters in Norway, 0.51 cubic meters in Finland, 0.49 cubic meters in Denmark, 0.41 cubic meters in Germany, and 0.27 cubic meters in France. For the overall European market, sales of thermal insulation materials are 90 million cubic meters per year, worth 40 billion yuan. In the huge market mentioned above, foam accounts for one-third. In other words, the annual sales of insulation materials composed of polystyrene, polyurethane and other materials in the European market exceed 30 million cubic meters, and the United States 20 million cubic meters. my country's insulation materials market started late, especially the market development of organic insulation materials is lagging behind. For a long time, a lot of use has concentrated on packaging. However, in recent years, with the development of economy and the entry of foreign technology, the use of organic materials in construction has achieved great development, limited to the amount of polystyrene and polyurethane used for color steel sandwich panels used in building factories Every year it exceeds 1.5 million cubic meters, of which a large amount of secondary foamed EPS is used. With the development of the economy, this market is bound to expand, and a large market will be replaced by XPS. XPS can be applied in the field of building energy saving and the amount of energy. The energy policy of the Chinese government is to "emphasize development and conservation", and put conservation first. Saving energy is still a strategic point of China's energy industry. In 1986, the Ministry of Construction promulgated the "Civil Building Energy Conservation Design Standards", and then further improved the standard indicators. Before the implementation of building energy efficiency standards, the cumulative area of residential construction in my country over the past year was nearly 8 billion square meters. Since 2000, the energy-saving renovation work of the original buildings with poor thermal environment or large energy consumption in the heating area has begun. In 2005, key cities and towns began to carry out building thermal environment and energy-saving renovation. XPS is very attractive in the renovation of old houses because of its excellent performances such as low thermal conductivity, lightness, high strength, waterproofing, anti-seepage, and ease of construction. During the Tenth Five-Year Plan period, there will be a huge development in our residential construction. Nowadays, the number of urban buildings is about 7 billion, of which there are more than 4 billion square meters of residential buildings. In the next ten years, 5.7 billion square meters of residential buildings will be built , Including 2.7 billion in cities and 3 billion in rural areas. Under this circumstance, the development of insulation materials should be industrialized. New housing will adopt energy-saving measures from planning, design, application of related materials and equipment, improve the quality of housing, and promote the use of new Materials, new technologies, new processes, promote the upgrading of the building materials industry. Therefore, to have a higher level of thermal insulation technology, thermal insulation materials, XPS is facing a huge market.

If you want to know more about it please do not hesitate to

contact me. WhatsApp:+86-15966835076.