do you really know EPE pearl cotton?

do you really know EPE pearl cottonEPE pearl cotton is a non-crosslinked closed cell structure, also known as polyethylene foam cotton, which is a new type of environmentally friendly packaging material. It is composed of low-density polyethylene grease through physical foaming to produce countless independent bubbles.

The Chinese name EPE pearl cotton structure non-crosslinked closed cell structure features water-proof, moisture-proof, shockproof, sound insulation and heat insulation. The other name is polyethylene foam cotton type packaging material, which is composed of low density polyethylene grease.

table of Contents

1 Overview

2 Application

3 Basic characteristics of technical parameters

4 Physical characteristics

5 Product features

6 Classification

7 Scope of market prospects

8 Material use

9 Special fiber for related products

Overview

It overcomes the shortcomings of ordinary styrofoam, such as fragility, deformation and poor recovery. It has many advantages such as water and moisture resistance, shockproof, sound insulation, heat preservation, good plasticity, strong toughness, recycling, environmental protection, strong impact resistance, etc. It also has good chemical resistance. It is an ideal substitute for traditional packaging materials.

application

Widely used in high-end fragile gifts such as car seats, pillows, electronic appliances, instrumentation, computers, audio, medical equipment, industrial chassis, hardware lighting, crafts, glass, ceramics, home appliances, spraying, furniture furniture, alcohol and resin Packaging, hardware products, toys, melons, inner packaging of leather shoes, daily necessities and other products. After adding the color antistatic agent and flame retardant, its outstanding performance is more obvious. Not only beautiful appearance, but also effectively prevent static electricity and ignition

The bonding products of EPE and various fabrics are good interior decoration materials for various vehicles and rooms. The composite product of EPE pearl cotton and aluminum foil or aluminized film has excellent anti-infrared ultraviolet ability, and it is a must-have item for some chemical equipment refrigerators and camping equipment car sunshade. Its pipes are widely used in industries such as air conditioners, baby carriages, children's toys, furniture, plumbing and plumbing.

Editing of basic characteristics of technical parameters

30-40 times high foam molding products, light weight, with certain firmness

Good flexibility and cushioning

Very low thermal conductivity and excellent thermal insulation

Independent bubble foam, waterproof material with almost no water absorption

High foaming and excellent water resistance make it very buoyant

Corrosion-resistant materials that are not subject to various chemicals

Not affected by various climatic conditions, excellent weather resistance

The independent bubble foam has a good sound and vibration proof effect

Excellent workability in cutting, bonding, extrusion, vacuum forming, compression forming, etc.

Foam material with fine bubbles, smooth appearance, colorable and beautiful effect

Production of flame retardant products through processing

Can be used to prevent static electricity

Physical characteristics

Item Unit Data

Density G / cm3 0.03

Cell structure-non-crosslinked seal

Tensile strength KG / CM2 3.40

Tear strength KG / CM2 2.60

Elongation% 125

Water absorption rate MG / CM2 0.01

Shrinkage (70-C)% 0.75

Thermal conductivity KCAL / M.H.C 0.02

Operating temperature -C -60 to +80

Softness-good

Shear strength KG / CM 1.8-3

Surface resistance ohm ordinary: None

Antistatic: 10 to the power of 9-11

Product feature editing

EPE Pearl Cotton Glue Coating Machine is a coating machine developed for the need to apply a large area of hot sol on sponge cotton (sponge, EVA) (especially some sheets that are not easy to handle by hand), which is convenient to use and very efficient. high. Especially suitable for deep processing of EPE pearl cotton industry (assembly, assembly, fitting, bonding, compounding). The glue design is based on product needs and different materials. The amount of glue can be adjusted. Its characteristics are all Closed, not easy to leak glue, easy to clean and drip glue; roller bearing external design, long life, low failure, non-stop maintenance when the glue is melted, does not affect production; completely solves the phenomenon of temperature overshoot, no yellow glue, with shovel resistance 1. High temperature resistant coating, it will not change color and black for many years; more importantly, it has even coating, high efficiency, and can reduce a lot of manual input.

Category Editor

Pearl cotton: ordinary pearl cotton, wax-free pearl cotton, super flat pearl cotton, encrypted pearl cotton, encrypted hardened pearl cotton, anti-static pearl cotton, PO coated pearl cotton, PE coated pearl cotton, aluminum foil coated pearl cotton, plating The color film is attached to pearl cotton, pearl cotton, PS board (pearl board), KT board (advertising board) \ fireproof pearl cotton, and pearl cotton bridging.

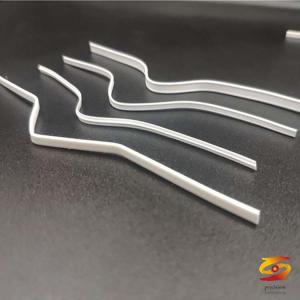

EPE profiled materials: tube-shaped, rod-shaped, L-shaped, U-shaped and various profiled materials, EPE components, EPE can also be processed into various sizes of EPE bags after coating.

Market prospects

Such as: buffering, protection, packaging materials, wood, sports equipment, etc. * Scope of application: EPE (Pearl Cotton) combination, honeycomb paperboard gluing, etc.

EPE is widely used in electronic appliances, instrumentation, computers, audio, medical equipment, industrial control cabinets, lighting, crafts, glass, ceramics, home appliances, spraying, furniture, wine and gift packaging, hardware, toys, melons, leather shoes Packaging of various products such as inner packaging and daily necessities. After adding anti-static agent and flame retardant, its outstanding performance is more obvious. EPE pearl cotton is also widely used in elastic lining of handbags, industrial sound insulation, thermal insulation materials, agricultural insulation materials, floating equipment for aquaculture, protective mats for sporting goods, rescue equipment for water operations, floor decoration for homes and hotels , Padding, etc. Its pipes are widely used in industries such as air conditioners, strollers, children's toys, and furniture. The bonding products of EPE and various fabrics are good interior decoration materials for various vehicles and rooms. The composite product of EPE and aluminum foil or aluminum-plated film has excellent anti-infrared ultraviolet ability, and is a substitute for some chemical equipment refrigerators and camping equipment car shades.

Material use

Because of its special advantages, it not only does not pollute the environment, but also can be recycled repeatedly, so EPE foam is a new type of material that will never decline in Chaoyang. With the advancement of time and the continuous development and application of products, EPE EPE foam materials will be more widely used in packaging and filling materials.

At present, the production of EPE EPE foam material is more developed in the Pearl River Delta. The use of this material is more common in all walks of life, and it has achieved good economic benefits for companies that produce and use this material. The results are very significant. Today, the production of this material is gradually expanding towards Zhejiang, Shanghai, Shandong and other provinces and cities. But in fact, the enterprises that have already put into the production line are far from meeting the needs of various domestic markets. Moreover, there are still many provinces and cities in China that are in a blank area. This new material is urgently needed to fill the needs of the packaging and filling industry.

Because EPE foam is a new type of environmentally friendly packaging and filling material. Its superior characteristics are more and more recognized by people, so its use will continue to expand and innovate. Especially in packaging and other industrial materials, it has better performance, lower cost, higher grade, beautiful appearance, and better effect than traditional materials. In addition, it is more significant in terms of packaging materials for agricultural and sideline products. At the same time, EPE EPE foam sheet can also be further processed, only need to prepare EPE laminating machine, laminating machine, the surface of EPE sheet is covered with HDPE film, aluminized film, plastic coated paper, plastic coated cloth, etc. After coating, the EPE sheet not only improves the mechanical strength, but also improves the original performances and prints various patterns and texts, and expands the product publicity. And the compounded sheet can be widely applied to the inner liners of box linings, life jackets, heat insulation, moisture-proof tents, etc. The economic benefits have doubled.

In addition, EPS (expanded polystyrene) packaging products cannot be recycled after use, causing white pollution and being banned internationally. In 1998, Europe and the United States and other countries promulgated a ban on the import of any products in EPS packaging. In 1999, China promulgated the ban on EPS fast food boxes in railways and other departments, so EPE pearl cotton packaging products will fully replace EPS packaging materials, will soon occupy the packaging market, and may replace Packaging materials such as paper and corrugated board boxes are also more beautiful than any packaging materials.

Related product special fiber editor

It is a three-dimensional crimped hollow fiber, which is processed into a ball-shaped cotton by a special ball-forming technology. The cotton ball is hollow inside and has a large air-permeable space, which is more warm and breathable. And after the product is quilted, it will automatically expand, even if it is machine washed, it will not be deformed. Mostly used for pillows.

Generally, three-dimensional 7D (thickness) * 51 (length) is used to make pearl cotton.

Foam shrinkage auxiliary-monoglyceride

In the production process of pearl cotton without adding monoglyceride, the finished product will shrink and become soft, so in the production process, anti-shrinkage auxiliary molecular distillation monoglyceride must be added.

Molecularly distilled monoglyceride is a high-quality and high-efficiency additive. It has the functions of stabilization, foaming, shrinkage, lubrication, antistatic, modification and anti-fogging. It is used in daily chemical, plastic, packaging and cosmetics. Widely used in other industries.

Molecularly distilled monoglyceride is an ideal auxiliary foaming agent and anti-shrinking agent. In order to meet the needs of environmental protection, Freon blowing agents will gradually be eliminated. It can be used as a foaming agent for high-foaming polyethylene and polystyrene, together with butane and other foaming agents, and has very good effects. Moreover, the surface of plastic foamed products using molecularly distilled monoglyceride is very smooth and bright without shrinkage.

Molecularly distilled monoglyceride is an excellent internal lubricant, which can reduce the friction between polymer molecules, thereby reducing the viscosity of the polymer melt and improving its fluidity. It has the advantages of good compatibility with resin, easy to disperse and suitable for transparent products. Its antistatic effect is very significant, which can reduce the formation and accumulation of static electricity in plastic products, reduce the dust adsorption of plastic products, and keep the transparency and clean and beautiful surface of the products.

If you want to know more about it please do not hesitate to

contact me. WhatsApp:+86-15966835076.