Description of PVC Yin Yang corner production equipment

Description of PVC Yin Yang corner production equipmentOverview of PVC Yin Yang corner production line machine:

The PVC Yin Yang corner production line machine manufactured by our company has the following improvements based on a few years ago:

1. PVC one-yin-yang angle production line machine can be upgraded to one-yin-yin-yang angle line production line machine with four out, one-out six, and one-out eight output line, which can increase output and reduce labor cost. Operation, and one out of four, one out of eight also requires only two people to control.

2. The old-fashioned punching machine of the PVC Yin-Yang angle production line machine has been improved into a porous punching machine with simple operation. It is not easy to break during the punching process, the production is stable, and the power is saved.

3. The PVC Yin Yang angle production line machine used SJ series single screw extruder at first, although the equipment is relatively cheaper, and the single screw eats pellets, the price of pellets is relatively expensive, because people To earn the price from powder to granules, at present, the raw material price of PVC yin and yang angle powders on the market is about 3000 to 4000 yuan, and the price of granules is more than 7000. If we continue to produce for several days, it will be long since Earn tens of thousands of dollars in extra investment, as long as you invest in equipment, raw materials must be invested every day. Our company has been developing and manufacturing equipment from the perspective of customers for 20 years, reducing costs for users, increasing output, and ensuring quality. At the same time, we can win a bigger market and profit.

The entire assembly line of PVC Yin Yang corner production line includes the following parts:

PVC powder screw feeder, high-speed mixing unit (various raw materials are evenly mixed at high temperature, automatically discharged to the cold mixer for rapid cooling for the host), SJSZ51 special Yin-yang angle conical twin-screw extruder, PVC out Four yin and yang angle molds, vacuum shaping box 4 meters, punching machine, special yin and yang angle traction machine (rubber is specially customized according to the yin and yang angle size block), cutting machine (yin and yang angle cutting blade), stacking rack, etc. It can also be equipped with a crushing and grinding machine, which will add some waste materials in the production process and add it to the raw materials after crushing and grinding to make products, which can be used for recycling.

PVC Yin Yang corner production line machine

A PVC four-yin and yang corner production line machine can directly replace the mold to produce PVC building corners, corners, corners, corners, and corner insulation. PVC corners are for wall corners and door edges. A new type of building material specially designed for difficult corner and window construction. It is a new type of corner protection product specially developed for the protection of internal corners of the inner wall. It is widely used in construction, decoration and corner reinforcement and protection during the renovation of old houses. It has changed the traditional use of manual or borrowed simple tools to fan and repair The method of the inner and outer corners of the wall.

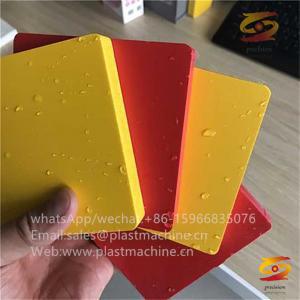

The characteristics of the yin and yang angle and corner protector produced by the PVC yin and yang angle production line machine:

PVC yin and yang corners and corner protection strips have the advantages of corrosion resistance, impact resistance, anti-aging, good adhesion, and full combination with putty, which greatly enhances the impact resistance of the corners and maintains the long-term beauty of the corners without being damaged. Various traditional building materials such as steel, wood and aluminum.

PVC after-sales angle production line machine service:

Before picking up the goods, the user can choose to debug the machine in our company, try out the product that the customer is satisfied with, and then pay the balance. Our after-sales staff will rush to the site before the equipment arrives at the user's factory. Design placement equipment, pipeline laying, circuit routing, and installation equipment. During the commissioning process, the main items of operation equipment, operation procedures and some troubleshooting methods are taught to the boot master. Generally, the equipment will be installed and debugged within 1-3 days.

If you want to know more about it please do not hesitate to

contact me. WhatsApp:+86-15966835076.