How rubber shields are produced

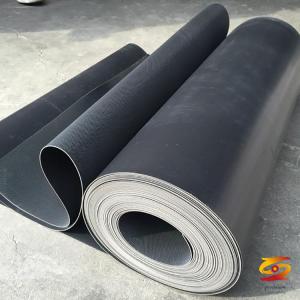

How rubber shields are producedThere are two types of shields that are common to us. One is pure black single-extruded rubber shields. This product often requires only one rubber extruder to produce it. We need to choose the rubber extruder model suitable for production according to the size of the product. For example, the 120 type rubber extruder and 90 type rubber extruder that we commonly use are often used for the production of single-color shields. In the production of this relatively large product, it is often necessary to use a high-temperature setting section and a combination of microwave vulcanization and hot air vulcanization for vulcanization. The other type of rubber shield is a two-composite rubber product. This product is a two-composite rubber shield made of a red rubber and black rubber. The shield is produced at the time of production. It is necessary to use a compound die to connect two rubber extruders for co-extrusion to obtain the product shape we need. When this product is produced, it usually uses a 65-type rubber extruder and a 90-type rubber extruder to produce the product we need. After the product is produced, it needs to be vulcanized. The final product is obtained by vulcanization. Shield strips are also different according to the use size and shape of the product. When we choose the production equipment, we should choose the most suitable production process and equipment according to the specific type and size of the product.

If you want to know more about it please do not hesitate to

contact me. WhatsApp:+86-15966835076.