Description

Introduction to MBBR Bio Media Extrusion Lines

The Moving Bed Biofilm Reactor (MBBR) technology is a cutting-edge solution in wastewater treatment, utilizing biofilm carriers to enhance microbial growth and pollutant degradation. Central to this technology is the MBBR bio media extrusion production line, which manufactures the specialized media essential for efficient treatment processes.

1.Key Components of the MBBR Bio Media Extrusion Line

①Vacuum Loader: Automatically feeds raw materials into the system, ensuring consistent input.

②Hopper Dryer: Removes moisture from materials like HDPE or PP, crucial for maintaining product quality.

③Single Screw Extruder: Melts and homogenizes the plastic, preparing it for shaping.

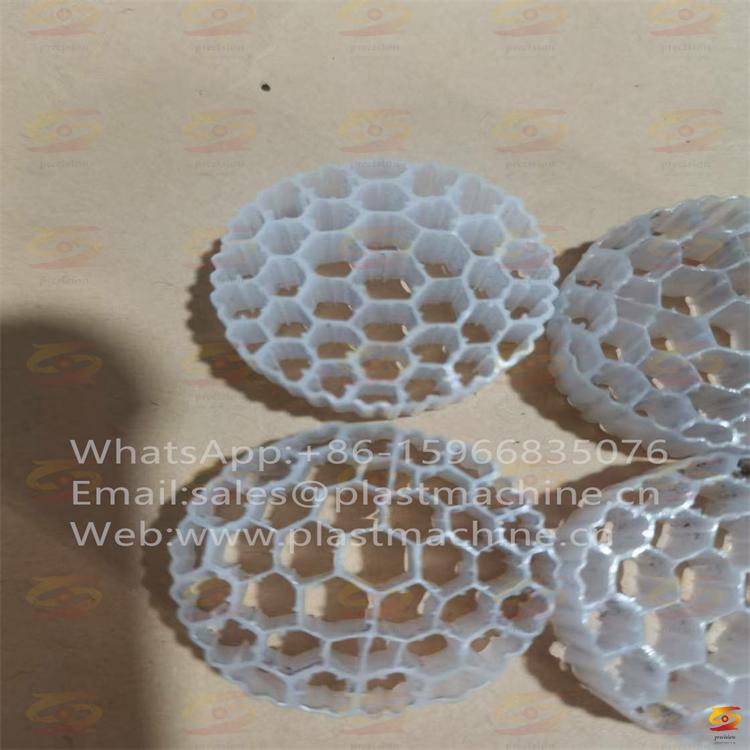

④MBBR Media Moulds: Shapes the molten plastic into specific designs (e.g., K1, K3) that maximize surface area for biofilm attachment.

⑤Vacuum Cooling Tank: Rapidly cools and solidifies the extruded media, preserving structural integrity.

⑥Water Cooling Trough: Further cools the media, ensuring dimensional stability.

⑦Haul-Off Machine: Pulls the media through the line at a controlled speed, maintaining uniformity.

⑧Cutting Machine: Precisely cuts the media to desired lengths, facilitating easy handling and application.

⑨Storage Silo: Collects and stores the finished media, readying it for packaging or immediate use.

2.Production Process Overview

Material Preparation: High-quality HDPE or PP pellets are selected for their durability and compatibility with microbial growth.

Extrusion: The pellets are melted and forced through specialized moulds to form the desired media shapes.

Cooling: The newly formed media is rapidly cooled to set its shape and enhance strength.

Cutting and Collection: The media is cut to specified sizes and collected for storage or shipment.

3.Applications of MBBR Bio Media and Extrusion Lines

Municipal and Industrial Wastewater Treatment: Enhances the efficiency of biological treatment processes by providing ample surface area for microbial colonization.

Aquaculture Systems: Maintains water quality by facilitating the breakdown of organic waste.

Recirculating Aquaculture Systems (RAS): Supports high-density fish farming by ensuring effective waste management.

Pond and Aquarium Filtration: Provides a habitat for beneficial bacteria, promoting a balanced aquatic environment.

4.Advantages of MBBR Bio Media Extrusion Technology

High Surface Area: Optimized designs increase microbial attachment, boosting treatment efficiency.

Durability: Materials like HDPE and PP offer long service life, resisting degradation in harsh environments.

Scalability: Modular design allows for easy expansion to meet growing treatment demands.

Energy Efficiency: Streamlined processes reduce energy consumption, lowering operational costs.

Customization: Ability to produce various media shapes and sizes tailored to specific treatment requirements.

5.Future Trends in MBBR Bio Media Production

Material Innovation: Development of new polymers and composites to enhance microbial compatibility and media longevity.

Automation and Smart Controls: Integration of IoT and AI for real-time monitoring and process optimization.

Sustainable Practices: Emphasis on eco-friendly materials and energy-efficient production methods.

Global Expansion: Growing adoption of MBBR technology in emerging markets, driving demand for advanced production lines.